There’s an increasing number of projects and schemes available to farmers and landowners that pay for carbon reductions or sequestration. Some of these schemes involve carbon offsetting, which can be a contentious topic. With limited independent advice available, it can be difficult to cut through the noise and detail.

Key takeaways

- Farmers will likely receive greater demands from their value chain to decarbonise with payment incentives to undertake new activities or hit targets. They may also receive increased marketing from companies wishing them to engage in carbon offsetting.

- Any practices should align with the farm’s strategic direction – don’t just follow the money.

- Each farm is starting from a different position and through historical work and perhaps the sheer luck of location, some farms may have more opportunities than others to be paid for carbon.

- Carbon offsetting can have various challenges associated with it: go careful!

- Carbon insetting offers a route for the whole food supply chain to decarbonise.

1. What’s the context?

a. Increased urgency to act on climate change

There’s an increasing urgency to act on climate change, as it becomes ever more real. Pressure from scientists and concerned citizens has added to the pressure on governments and companies to act. No business or sector is considered exempt.

b. Ambitious company commitments

In the UK, we have ambitious commitments at a national level, and in recent years, many of the world’s biggest food companies, together with other sectors, have committed to a goal of net zero emissions. This includes companies such as Nestle, Tesco, Sainsbury’s, Danone, PepsiCo, to name just a few. While there is sometimes criticism over the realistic nature of some of these goals, it is what the science demands. As such, carbon is becoming increasingly valued as something to manage and invest in – and so landowners and farmers can expect increased support or demands from all the organisations they interact with (banks, insurance companies, landowners, supply chain etc).

Achieving “net zero” is a monumental challenge for many companies because success often depends on effective collaboration and a willingness to act by others in the value chain, as well as competitors. Presently, carbon offsetting and investment in nature-based solutions is a common way to help companies to achieve their net zero goals. Yet it’s a commonly held principle that carbon offsets should not be a substitute for direct business emissions reduction.

c. An increasing understanding of the role farms can play

Farm businesses are in a unique position, as they can sequester and store carbon. Very few other businesses can do this. The huge potential to reverse declines in soil health and subsequently increase the carbon stored in our soils, as well as in above-ground biomass, is increasingly recognised and understood by wider society. Subsequently, a surge in schemes to pay farmers and landowners for carbon is underway. We provide a free Farm Carbon Calculator tool for farmers to help them understand the carbon position.

2. Don’t just follow the money

The increasing number of schemes for farmers and landowners to improve their carbon footprint can bring many exciting opportunities, supporting changes small and large.

When facing any new opportunity, it’s important to take time to consider how it aligns with your farm’s direction. Consider the time that will be invested and the various consequences. It’s also always worth speaking to others too, who will help provide different perspectives, especially anyone who already implements similar practices or participates in the same project or scheme.

Each farm is starting from a different position and through historical work and perhaps the sheer luck of location, some farms may have more opportunities than others to be paid for carbon.

3. Getting paid for carbon: key concepts and watch-outs

What schemes already exist?

Indirectly paying for carbon, there are various schemes in the UK already that pay farmers and landowners to undertake sustainability measures, which will likely reduce a farms carbon footprint. Some schemes are nationwide, while many are specific to a region or supply chain. For example:

- National government environmental schemes such as the Sustainable Farming Incentive and Local Nature Recovery in England, and Agri-Environment Climate Scheme in Scotland.

- Water companies schemes paying farmers to enhance soil health and reduce pollution.

- The selling of biodiversity units to developers via Biodiversity Net Gain

- Specific grant funded initiatives such as Farm Net Zero

- Specific supply chain projects

There are fewer schemes that pay specifically for carbon reduction or sequestration. The most well-known are:

- For woodland creation, using the Woodland Carbon Code standard.

- For peatland restoration, using the Peatland Code standard

Payments for increasing soil carbon stocks is relatively new in the UK. Organisations such as Agreena, Soil Capital and Trinity AgTech have launched payment schemes. And separately, work is underway to launch a Soil Carbon Code which will recommend minimum requirements for high-integrity soil carbon markets. If taken-up and schemes align to this, there will be some much needed clarity and consistency to this burgeoning space, building more trust and rigour.

There are also projects working to establish a Hedgerow carbon code and Agroforestry Carbon Code, providing more standardised and agreed methodologies, which may unlock new payment schemes.

With all these schemes, the way payments occur can vary. Some schemes pay for a farmer or landowner to implement specific practices for which an assumed amount of carbon will be sequestered or removed based on models, while other schemes may be outcomes-based, paying for a measured improvement in carbon.

How carbon is rewarded in farm-based schemes

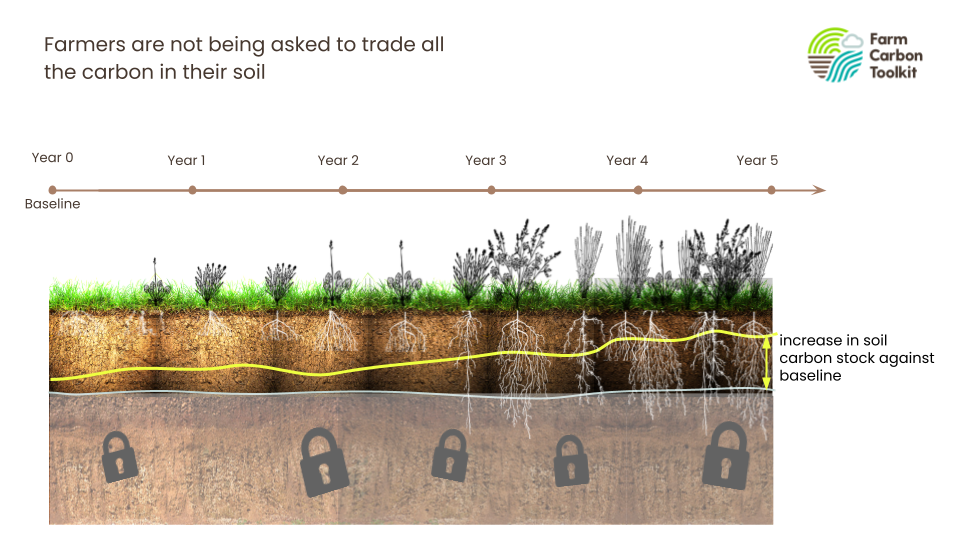

Farmers and landowners are not being “paid” for (or being ask to trade) all the carbon stored on their land (the “stock”). Typically, projects are interested in the change over a period. For example, the carbon emissions avoided by implementing a new practice or technology. If a farm is being rewarded for increasing its soil carbon stock, it’s for the increase against a baseline over an agreed time period. In some cases, it may alternatively be the improvement compared to a local average or benchmark.

Carbon offsetting vs carbon insetting

Some payment schemes involve carbon offsetting or carbon insetting:

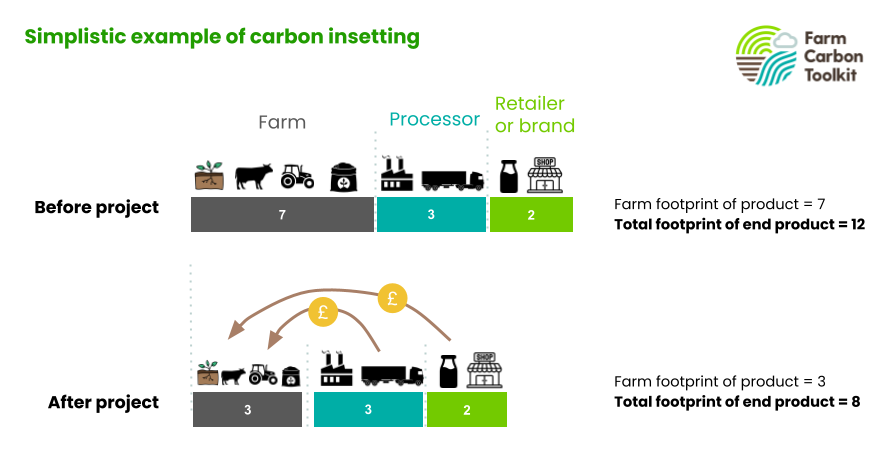

Carbon insetting refers to investment occurring within the same supply chain to reduce or sequester carbon emissions. A good case study of this is with Nestle and First Milk, where farmers have received a ’sustainability bonus’ for taking practical measures that protect and enhance natural assets on their land, many of which had a carbon benefit which are being quantified.

The benefit of carbon insetting projects is that all the organisations in the supply chain benefit from the carbon reduction and there’s less complications or confusion over who claims the benefit.

It should be mentioned that carbon insetting does lack a clear definition and is sometimes used in schemes that can’t guarantee the reduction is taking place within the value chain. This is common for commodity-based supply chains, where traceability of a crop is a challenge. To get around this, projects have applied a concept called supply sheds (more details here).

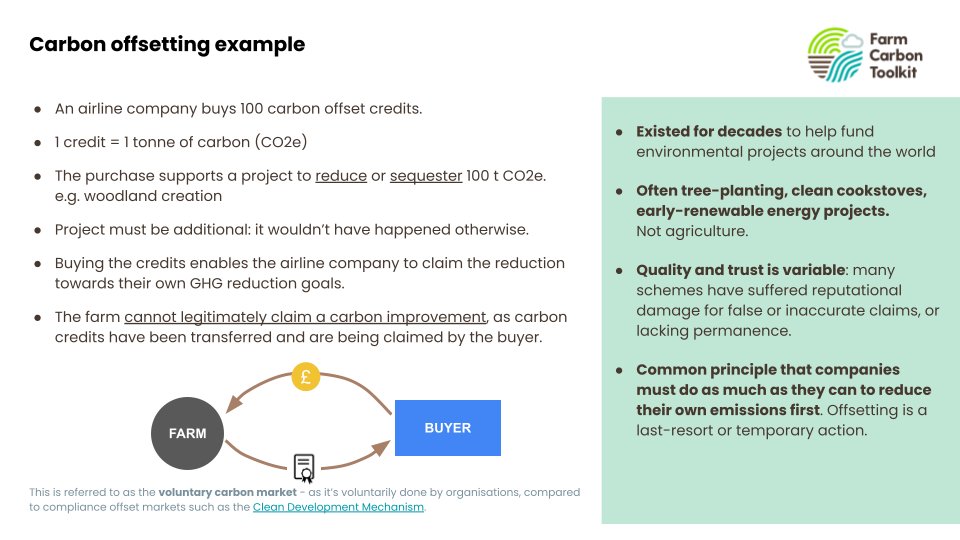

Carbon offsetting is a different approach involving organisations outside of the farm’s direct supply chain. Carbon offsetting has existed for decades as a means to help fund environmental projects, particularly in the global South. They have traditionally been for projects involving tree-planting, the provision of clean cookstoves and renewable energy. Their application to agriculture is relatively new.

A carbon offset refers to a reduction in GHG emissions – or an increase in carbon storage – that is used to compensate for emissions that occur elsewhere. One carbon credit equals one tonne of CO2e avoided or removed. These credits are essentially traded between organisations. So if you’re a farm that’s sold a carbon credit, the buyer of that credit will be claiming this as their emission reduction and as a farm and you may no longer legitimately be able to claim this carbon reduction as your own. It is double-counting for both the buyer and seller of the carbon to claim credit and gives a false impression of our progress to address climate change.

The quality and trust of carbon offsetting schemes are variable and we suggest taking care when engaging with this space. Over the decades, many schemes have suffered reputational damage for false or inaccurate claims, or lacking permanence (here’s one prominent example).

It’s also a common principle that companies must do as much as they can to reduce their own emissions first. Offsetting is a last-resort or temporary action.

Permanence

Permanence refers to how long the carbon is kept out of the atmosphere. For reducing climate risk, the longer the better.

The permanence of carbon is far easier to quantify and verify for woodlands and forestry, than for soils. This is a major reason why carbon offsetting projects are less prevalent in agriculture.

Improvements to soil organic carbon carries a higher risk of reversal compared to trees and hedgerow, due to the possibilities of short-term changes in management practice. Therefore agricultural carbon offset projects are often considered lower quality in relation to others.

The standard convention in offset markets has been to guarantee that carbon is kept out of the atmosphere for 100 years. As this is not practical for soil carbon where credit periods are often limited to 10-15 years. In the USA, Nori offer short-term soil carbon credits that expire after 10 years. In Europe, Soil Capital has a 5 year crediting period, in which farmers can earn and generate credits, followed by a 10 year retention period. Carbon Farmers of Australia must choose between 25 and 100 year permanence guarantee.

Additionality

This is pertinent for quality carbon offsetting projects. It’s about whether the payment a farmer or landowner receives plays a decisive role in helping remove carbon from the atmosphere. Additionality is essential for the quality and credibility of the carbon offset market. Yet, especially in farming, its determination is subjective and deceptively difficult. Is this payment providing the make-or-break difference, or was it going to happen anyway?

Carbon leakage

It’s important to ask, could this project result in an increase of emissions elsewhere? Changes in farm management practice might deliver more carbon sequestration in one place, but, if the result is less food being produced, it may have the effect of creating a bigger carbon footprint elsewhere. This is because imported food may have a bigger carbon footprint than home grown produce. This issue is known as “carbon leakage”.

Taking a global food systems perspective into any project can help consider any unintended consequences and will help shape a better, more impactful project.

4. Where to find further information

Click here to download the slides from our webinar (PDF): Getting Paid for Carbon, presented on the 27 April 2023 as part of our Farm Net Zero project.

- On our blog: Demystifying farm carbon offsetting: three watch-outs for farmers

- On our blog: Who owns the carbon?

- Water companies schemes paying farmers to enhance soil health and reduce pollution.

- The Taskforce on Scaling Voluntary Carbon Markets: a private sector-led initiative working to scale an effective and efficient voluntary carbon market

- Offset Guide: a guide for organisations seeking to understand carbon offsets.

- The Oxford Principles for Net Zero Aligned Carbon Offsetting.

- Broekhoff, D., Gillenwater, M., Colbert-Sangree, T. & Cage, P. Securing Climate Benefit : A Guide to Using Carbon Offsets. 59 (2019).

- 10 myths about net zero targets and carbon offsetting: signed by 41 scientists.

Its all too easy to forget the crucial part that we as farmers play in creating a profitable industry that can be sustained long term and investing in skills and people development can help businesses to grow.

Its all too easy to forget the crucial part that we as farmers play in creating a profitable industry that can be sustained long term and investing in skills and people development can help businesses to grow. The lifeblood of any business is the workforce – finding skilled and committed workers can be a challenge for any business, but especially on farms. There is a shortage of younger entrants to the farming industry,

The lifeblood of any business is the workforce – finding skilled and committed workers can be a challenge for any business, but especially on farms. There is a shortage of younger entrants to the farming industry,

Recent Comments